G&A Harris - Production Tracking System

Designing and building an order tracking system for manufacturing.

The Problem

G&A Harris produce a range of custom metal products designed for the construction industry. Almost all their orders are custom to the clients specifications, with dozens of orders coming in each day.

Order data, dimensional data and manufacturing status were tracked using a paper based system which followed the order around the facility. This system presented a number of issues:

- Order data was often lost or misplaced during the manufacturing process.

- Customers would often call to check on the status of their order, and staff would need to spend time tracking down the order.

- There was no clear way to understand at a high level what was being produced through the facility.

In addition, the pricing of jobs was a clear pain point. This process was completed manually and required an intricate knowledge of the companies pricing structure. This meant that the process could only be completed by select staff members, and was often a bottleneck in the order process.

Delivering Value Quickly

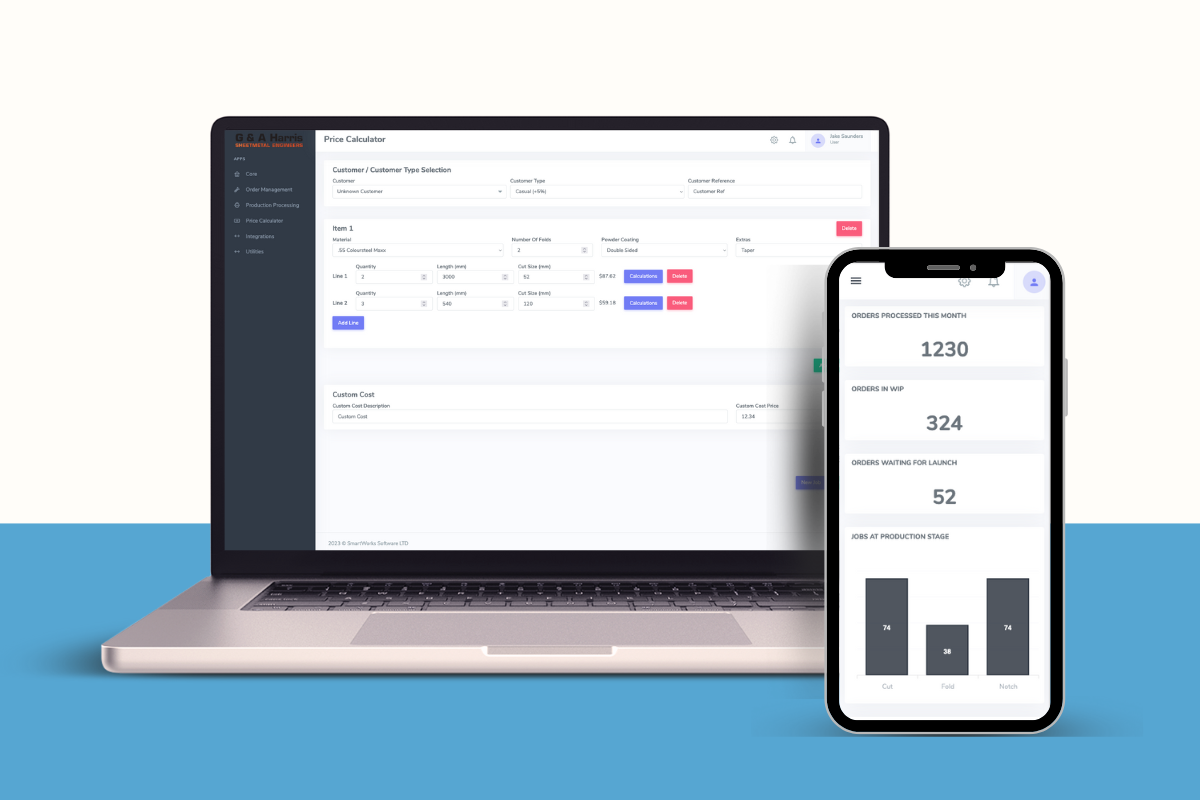

As with all our projects, we wanted to identify where we could deliver the most value as quickly as possible. Working with the team, we determined that we could develop and deliver an order pricing system ahead of delivering a full order tracking system. This would alleviate the initial bottleneck in the order process and allow us to gather early feedback on software usability.

We created a web based system, where order data would we entered and the pricing calculated on a cloud based app. This approach delivered a number of significant advantages:

- Staff could access the system from any device, including tablets and phones.

- We could easily update the system with new pricing rules and changes to the pricing structure without requiring staff to install new software.

- We could easily integrate the system with the existing accounting software (Xero), allowing for automatic retrieval of customer data and pricing information.

After working together to understand and systemise the pricing structure, we were able to deliver the pricing system in just 4 weeks. This system was immediately adopted by staff and significantly increased the number of orders that could be quoted each day. Order processing time was also reduced significantly.

Order Tracking System

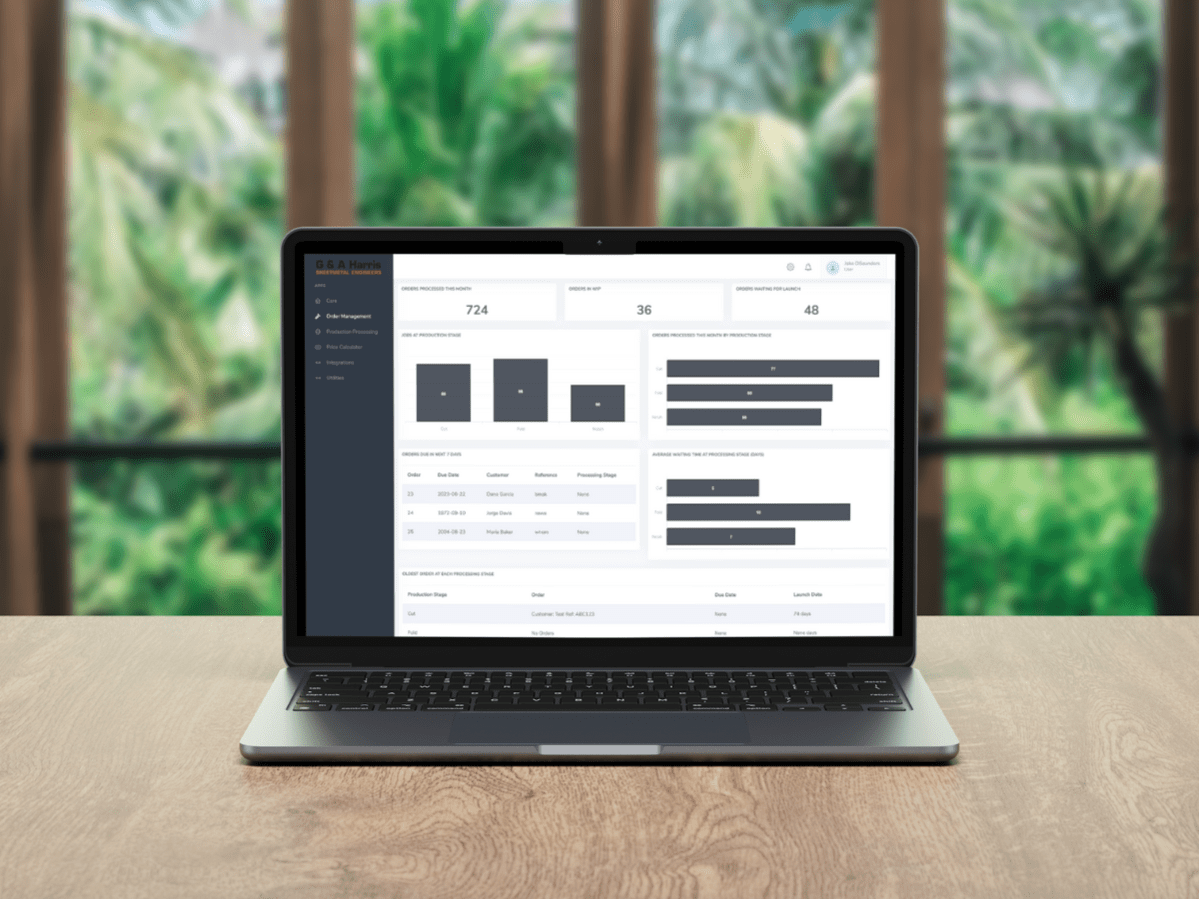

With the pricing system in place, we were able to begin work on the order tracking system. This system was designed to track orders from the moment they were received, through to manufacturing and delivery. The system was designed to be used by all staff members, from office staff who received the orders, through to manufacturing staff who completed the orders.

The system was designed to be as simple as possible, with a focus on providing the information that staff needed to complete their tasks. Information was also accessible on any device across the facility and could be updated in real time.

A key challenge in the design was the variability of the manufacturing process. Each order was unique, and the manufacturing process could change depending on the order. The software suite was designed to be as flexible as possible, allowing users to create custom routings for each order without the need for developer input.

Results

The order tracking system was delivered on time and under our initial cost estimate. G&A Harris have immediately adopted the software and have seen a number of significant benefits:

- Order prioritisation was completely automated, with a FIFO system in place to ensure that the most urgent orders were completed first.

- The time spent keeping customers updated on the status of their order was significantly reduced, with a view to creating a self-serve customer portal in the future to fully automate this process.

- A number of production dashboards were created, allowing management to see at a glance how the facility is performing and react to changing business conditions.

Conclusion

The project was a great success, and has allowed G&A Harris to significantly increase the number of orders they can process each day. The system has been well received by staff, and has allowed management to make more informed decisions about the business.

We continue to work with G&A Harris to improve the system and add new features. We are currently working on integrating the system across each area of the production facility, and are looking at ways to further automate the order process. We are happy to report that the app has achieved 100% uptime since launch.

Client Feedback

"We have a stronger level of control and knowledge of WIP and we can also better budget based on current workloads."

We first partnered with Smartworks and Jake to help us with some automation within our pricing. Jake very quickly understood our needs and within a 4 week period had developed us and online platform which contained a database of all of our materials, lengths, sizes, costings which could automatically cost jobs for us.

Once our pricing was sorted, we then moved on to the Manufacturing tracking stage, where Jake with his expert knowledge of manufacturing, lean systems and computer software probed us and brought to the table many ways of making our MS come to life. Jake probed a lot at the start of this project and wanted to be very clear on the direction we were heading to ensure alignment from all parties.

Fast forward 4 months and we have now set up barcoding and tracking for every job we have on our shopfloor, our operators all have specific log Ons so we have extra traceability on our products, we can automatically track and calculate pricing for any jobs within the system. Our team on the shopfloor are more engaged with how they manage their workload, we have a stronger level of control and knowledge of WIP and we can also better budget based on current workloads.

We agreed on a budget for the manufacturing system and were extremely pleased when the project came in at 85% cost of the budgeted figure.

Jake being based in the UK and our business in NZ was handled with no trouble at all, Jake would regularly touch base and set up meetings with us at antisocial hours in the UK to ensure the project was on track and handle any bugs/fixes developments we required.

Our next steps are to continue to work with Jake and develop our own flashing drawing application, where our customers can place orders on their mobile devices/laptops which will automatically cost them and add them to the production tracking system once accepted by our team here.

Matt Lehmann

G&A Harris